The landscape of material handling has undergone a profound transformation in recent years. Industries across the globe are increasingly turning to advanced technologies to improve efficiency, reduce errors, and cut costs. One such technological breakthrough is the use of vacuum grippers. These devices, often integrated with robotic systems, are reshaping the way materials are handled across a wide array of industries. In this article, we will explore how vacuum grippers are revolutionising material handling systems, enhancing precision, and driving innovation in manufacturing, logistics, and beyond.

Understanding Vacuum Grippers

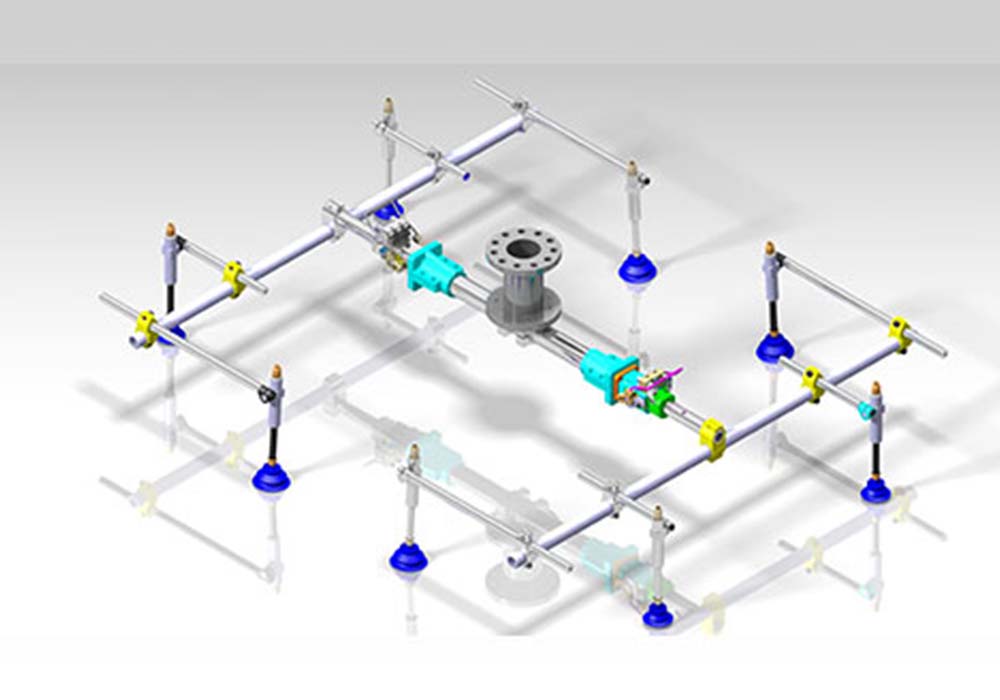

At its core, a vacuum gripper is a device that uses suction to lift and move objects. It operates on a principle similar to that of a vacuum cleaner, generating a negative pressure within a pad or cup that attaches to the surface of an object. This suction force allows the gripper to securely pick up and manipulate materials, making it an ideal tool for automated handling systems. The gripper’s design typically consists of a suction cup, a vacuum pump, and a system of hoses that maintain the airflow.

Vacuum grippers come in different types depending on the specific application. Single-pad grippers are simple devices that use one suction cup to lift objects, typically used for small or lightweight materials. Multi-pad grippers, on the other hand, use several suction cups to provide a more even and secure grip. These are often used in applications that involve larger or heavier items, ensuring better distribution of weight and minimizing the risk of damage to delicate materials.

Some industries require customized vacuum grippers designed to meet unique handling needs. For example, grippers with specialized materials and shapes can be built to handle irregularly shaped or fragile objects. By incorporating different materials such as silicone or foam, vacuum grippers can be tailored to work with a wide variety of surfaces, from smooth to textured, allowing businesses to use them in diverse operations. Explore EPick for a safe gripping solution.

Advantages of Vacuum Grippers in Material Handling

Vacuum grippers offer numerous advantages that make them a game-changer in material handling systems. One of the most notable benefits is their ability to provide enhanced precision and control. When integrated into automated systems, vacuum grippers can perform pick-and-place operations with extreme accuracy, reducing the likelihood of errors. This is particularly important in industries like electronics manufacturing, where precision is critical for assembling components.

Another significant advantage is improved efficiency. Vacuum grippers can pick up and move objects much faster than traditional manual handling methods. With the addition of robotic arms or conveyors, vacuum grippers can handle multiple items simultaneously, enabling high-speed production lines and reducing bottlenecks. This increased speed not only accelerates the production process but also minimizes downtime, leading to higher throughput and reduced operational costs.

In addition to speed and precision, vacuum grippers are highly adaptable. They can handle a wide range of materials, including fragile items, heavy objects, and everything in between. The ability to pick up various shapes, sizes, and weights makes vacuum grippers ideal for industries with diverse product lines.

Key Applications of Vacuum Grippers

The versatility of vacuum grippers extends across various industries, each benefiting from their efficiency and precision. In manufacturing and assembly lines, vacuum grippers play a crucial role in ensuring that materials are moved smoothly and quickly. The automotive and electronics industries, for instance, rely on vacuum grippers to handle delicate parts without causing damage. Their ability to lift and place components with exacting precision helps improve the quality of the final product, while also speeding up assembly processes.

Warehousing and logistics operations also benefit from vacuum grippers, particularly in the handling and packaging of goods. With the rise of e-commerce, warehouses must process large volumes of orders quickly and accurately. Vacuum grippers can be used in automated sorting systems to pick items, pack them, and prepare them for shipment. This leads to faster order fulfilment and improved customer satisfaction, which are critical in the competitive world of online retail.

Technological Innovations in Vacuum Grippers

Vacuum grippers have evolved significantly with advances in technology. One of the most notable developments is the integration of vacuum grippers with robotics. Robotic arms equipped with vacuum grippers can perform tasks autonomously, improving both efficiency and consistency. These robotic systems are particularly useful in industries like automotive manufacturing, where repetitive tasks are common. With the ability to work 24/7, robots equipped with vacuum grippers can ensure uninterrupted production and reduce the need for human intervention.

Another innovation in vacuum gripper technology is the rise of smart grippers. These devices are equipped with sensors and connected to the Internet of Things (IoT), enabling real-time monitoring and data analysis. This integration allows businesses to track the performance of their vacuum grippers, monitor suction levels, and predict when maintenance is needed. By leveraging IoT, smart grippers can also be programmed to optimize their performance, adjusting suction strength based on the size or weight of the material being handled.

Conclusion

Vacuum grippers are undeniably transforming material handling systems across multiple industries. From improving precision and efficiency to enabling the automation of complex tasks, these devices are playing a pivotal role in the evolution of modern manufacturing, logistics, and assembly processes. While challenges remain, such as initial costs and maintenance requirements, the advantages of vacuum grippers far outweigh the drawbacks.